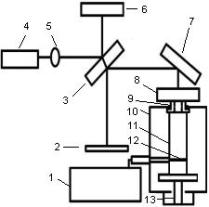

1. Digital temperature controller

2. Viewing screen

3. Beam splitter

4. He-Ne laser

5. Beam expander

6. Fixed mirror

7. Folding mirror

8. Movable mirror

9. Quartz tube

10. Oven

11. Specimen

12. Temperature sensor

13. Quartz base

Features

Compact structure

Various types of specimens

Low power consumption

High accuracy

Introduction

The LETI-30 Thermal Expansion Experiment utilizes the principle of optical interference to measure the thermal expansion of materials with high precision. The apparatus is designed for use with a Michelson interferometer, an oven, and a temperature sensor, which work together to provide accurate measurements of how materials expand or contract with changes in temperature.

The core component of this experiment, a Michelson interferometer, is used to measure tiny displacements in the specimen due to thermal expansion. The precision of the interferometer allows for measurements at the order of a half wavelength of the He-Ne laser, providing highly accurate results. The specimen is placed inside an oven, where its temperature is carefully controlled using a temperature sensor. This ensures that the material experiences a uniform and predictable temperature change during the experiment.

The specimen ends in the oven are isolated with quartz, ensuring that any thermal expansion occurring is primarily attributed to the specimen itself, without interference from the oven or other components. The displacement caused by thermal expansion is measured by counting the number of interference fringes that pass as the specimen expands. This method allows for a precise calculation of thermal expansion.

By conducting the Thermal Expansion Experiment, students will:

1. Understand the Principle of Optical Interference:

- Learn how a Michelson interferometer can be used to measure tiny displacements in a specimen caused by thermal expansion.

2. Learn How to Measure Thermal Expansion:

- Understand the process of measuring thermal expansion with high precision, using interference fringes as an indicator.

3. Calculate the Thermal Expansion Coefficient:

- Derive the linear thermal expansion coefficient of various materials based on the observed displacement and the known laser wavelength.

4. Explore Material Behavior with Temperature:

- Gain insight into how different materials expand when heated, and how to experimentally determine their expansion properties.

This experiment offers significant educational value for students studying materials science, thermodynamics, and experimental physics. Students will develop hands-on experience with precision measurement techniques and learn about the behavior of materials under thermal stress. By utilizing the Michelson interferometer and counting interference fringes, students can perform high-accuracy measurements and understand the physics behind thermal expansion at a fundamental level.

The instruction manual of LETI-30 Thermal Expansion Experiment comes with:

- Experimental Configurations: Detailed instructions on how to set up and use the interferometer, oven, and temperature sensor.

- Principles: An explanation of the theory behind thermal expansion and optical interference.

- Step-by-Step Instructions: A guide for conducting the experiment, making sure students can achieve reliable and accurate results.

For further information on the experimental theory, detailed setup, and the specific uses of the LETI-30 Thermal Expansion Experiment, please refer to the Experiment Theory and Contents . This apparatus provides an invaluable tool for students to learn about thermal expansion and optical interference in a hands-on, interactive way.

Specifications

| Description | Specifications |

| He-Ne Laser | 1.5 mW@632.8 nm |

| Specimens | Copper, aluminum, and steel |

| Specimen Length | 150 mm |

| Heating Range | 18 °C ~ 60 °C, with temperature-control function |

| Measurement Accuracy of Temperature Change | 0.1 °C |

| Display Value Error | ± 1% |

| Power Consumption | 50 W |

Error of Linear Expansion Coefficient | < 3% |

Part List

| Description | Qty |

| Thermal Expansion Experiment Unit | 1 |

| He-Ne Laser (LLL-2-A) | 1 |

| Plane Mirror | 2 |

| Power Cable | 1 |

| Lift Tool | 1 |

| Manual Counter | 1 |

| Aluminum Alloy Specimen | 1 |

| Copper Alloy Specimen | 1 |

| Steel Specimen | 1 |

1. Digital temperature controller

2. Viewing screen

3. Beam splitter

4. He-Ne laser

5. Beam expander

6. Fixed mirror

7. Folding mirror

8. Movable mirror

9. Quartz tube

10. Oven

11. Specimen

12. Temperature sensor

13. Quartz base